240Z KNOWLEDGE: The S30 Steering system and options post

Time for another geeky deep-dive into a not-so-common Datsun 240Z / Nissan Fairlady Z (S30) technical topic: The original steering system.

Disclaimer: As usual with my knowledge posts, i put this together over the course of years, spent countless hours on this, bought rare factory documents and literature for reference and tried my very best to get all information from trustworthy and official sources. But still i cannot guarantee that all information is 100% correct. Sometimes not even the official factory documentation is really clear. Let me know if you found a fault.

Also please ask before you use any of this! As with all my knowledge posts, i update them every now and then with my latest findings and try to keep them actual.

1. Introduction

The early S30 chassis steering system may not be the most interesting part of the car. Except for the steering wheel it’s not a classic tuning area like brakes, the transmission or the suspension system. Most people never touch it as long as it works, not even in motorsports. So why dedicate a special post to it?

Well, i just collected a lot of data about it over the years. Much which i have not seen published online yet – probably due to the unpopular topic. I have also restored my complete steering system, and thought it might be interesting for the “otaku” to get some detailed background information on one of the lesser talked about topics.

2. The System

2.1 General information

The english / american version of the 1972 Datsun 240Z Introduction bulletin booklet describes the 240Z Steering system as following:

The Steering Assembly is a direct-acting rack-and-pinion type with a gear ratio of 17,8:1 [–> see also later for more details on the steering ratio], providing sharp light and acurate control under all conditions. It consists of a rack bar and toothed pinion, both working in the plain bearing of the housing. Backlash is held to 0mm (0inches) by the retainer and the retainer spring

The american “introduction of the 240Z” bulletin additionally highlits the advantage of the rack-and-pinion system:

In another issue of the “introduction of the 240Z” (volume 125) following additional information is written:

The japanese “introduction of the fairlady Z” technical bulletin has it described a fair share more detailed on multiple pages. It mentions how the whole system works, how parts are connected, etc, but also how rigid and stable the system is, while beeing lightwight and direct and with easy maintenance. Here two pages are shown from that book:

2.2 The Meaning of R25N and RP15L

In the Japanese 1978 Nissan “steering maintenance manual” you can find a lot of background information on the Nissan Steering systems, including the one used in the S30Z.

For example you get a nice classification of the various Steering systems used by Nissan and in which car they were used in:

The top path translates to:

Steering gear – Recirculating ball type – For Passenger Cars / for trucks

The yellow marked path marks the “Fairlady Z” system:

Steering gear – Rack and Pinion type – Cherry FII / Fairlady Z

The bottom path means

Steering gear – Worm Roller type – For Patrol (nissan Patrol car?)

In the table shown below, you can see that the System Name of the one used in the Nissan S30 Chassis (And the nissan Cherry FII) is the R25N (RP15L) type.

What does that mean? Luckily the same book also provides the answer with the naming key:

Note that the naming convention changed in August 1982 (Showa era, year 57), so the overview shows two different systems in one table:

From left to right (bottom to top):

V = Variable | empty = constant

B = RB = Recirculating Ball type | R = RP = Rack and Pinion type

Two digits: For RB type: “Center Distance” | For RP Type: Rack Diameter (= Conventional center distance)

S = L = Yoshiwara Plant | T = A = Atsugi Auto Parts | P = B = Japan Power Steering | J = Automotive Equipment | N = NSK | K = Koyo Seiki

A = Difference in gear rations, valves, etc | empty = No variable ratios / gearing

That means for the Z steering rack

_RP15L_

Constant, Rack & Pinion type, 15mm center distance, Made at Yoshiwara plant, without variable ratios

When it comes to the R25N Name i’m not sure if it was the same type, but with the older / newer naming convention and manufactured at NSK, or something else.

In the remaining same book and other documentation by nissan, you can only ever find the “RP15L” name used for the S30 cars, so i’ll stick with that one too.

And in case you are wondering: The “Yoshiwara plant”, where the S30Z steering system was built, is the same factory that was renamed to “JATCO” (Japanese Automatic Transmission Co.) and built the Automatic transmission of the Z cars.

The Yoshiwara plant is also known as the Fuji plant, as it is located in Fuji city. Here’s a picture with some information from the Nissan 1964-1973 Chronicles book:

2.3 Specification

From the 240Z introduction bulletin vol 125:

Here are some additional spexifications from the 1972 USDM FSM, which confirms a lot of other data in this post.

Here are some more detailed specifications like the amount of bearings, grease used, different adjustment shim part numbers, installation torque, etc of the Fairlady Z RP15L system, but nothing important that haven’t been already mentioned in this post.

2.3.1 Differences to the Cherry FII RP15L

In the below table, you can see an overiew / comparison of the different features of the different systems used in various cars.

The main specification difference between the S30Z and the Cherry FII RP15L type system is the fact that the Fairlady / 240Z uses an bellowes (see later in this post), while the FII got a lip type or steel ball collapsable steering column (3rd colum from left)

Additionally in the same book in a later section you can find another difference to the Cherry FII RP15L system: The side rod inner ball joints are mounted differently:

2.4 Development

In the Datsun 240Z engineering development book by Hitoshi Uemura (one of the original S30 design engineers), you can find some background information on the development of the steering system:

– The proven rack-and-pinion system was used as in the Laurel C30 (this information is also confirmed in the JDM fairlady introduction service bulletin.)

– Initially it was considered that the american market would require a power-steering system, but a rack-and-pinion power steering system was not ready during the time of the S30. Instead the RB (Recirculating Ball) type Power steering from the Nissan Cedric was used until the release of the S130 in 1978, when Rack-and-Pinion power steering became available. This means Rack-and-Pinion (without power steering) and Recirculating Ball (with Power steering) steering systems coexisted for a while.

–> i want to personally Note that i have not yet seen any 240Z or early Fairlady Z from the S30 generation with power steering, but maybe i missed something or he was refering to some development setups?

2.4.1 Turning radius

Aidditionally i found this funny side-note from Hitoshi Uemura’s book about the steering radius, geometry and their effects in the Z:

The steering colum in the 240Z is a Bellowes type collapsable steering colum, that was later (in the 260Z) replaced with a steel ball collapsable steering column. The following details are written in the vol. 125 240Z introduction bulletin:

The Japanese Fairlady Z Introduction bulletin additionally mentions that the colum is in the axle of the driver movement in case of the crash to absorb some of the crash force, while the collapsable system is there to create minimum damage to the driver. The mount is designed specialyl with a focus that the driver cannot accidentally get his hands or other body parts behind in case of a crash.

Heres a more detailed look at the single components from the 172 FSM:

Here’s a more detailed view of all the single parts from the Japanese 1973 Fairlady Z parts manual:

In the Japanese Fairlady Z introduction book, the steering column is described very detailed on multiple pages, one of the pages shown here describe the function of the bellowes lower column tube and the steering column mounting bracket:

2.5 Steering rack-and-Pinion system details

The american documents dont provide any additional details which haven’t been mentioned allready. The general section of the Steering manual booklet mentions the advantages of the rack-and-pinion system being lightweight and simple by design, therefore it was used in the Cherry FII and Fairlady Z:

Here’s a closer look at the complete Rack-and-Pinion assembly from the S30Z from the Japanese Fairlady Z Introduction bulletin:

Again here a detailed look at the single components from the 172 FSM

In the Steering rack service booklet, you can find even more detailed exploded view drawings of the whole system:

2.6 Steering wheel details

If you are into the 240Z / Fairlady Z. You will notice one of the more talked-about topics is the three-spoke steering wheel, or better: the many variants of it. I will not go into the details of the many different (standard and optional) steering wheel versions, but in this post I’ll focus on two of the major steering wheel changes and the reasons behind them:

2.6.1: Holes for safety

Most steering wheel enthusiasts will know that there are early and later types of steering wheels. the early ones didn’t have any holes, but just a punched pattern on the three spokers. While at a later version has actual holes in the sames position.

The reasons of the change (starting from HLS30-21001 and HS30-00501) can be found in the “Introduction of safety devices” service bulletin, but also in the “late 1971 240Z model introduction” bulletin:

Here is an early steering wheel (without the holes) from the “Z-story” book:

The Japanese Fairlady Z introduction book also specifically mentions the thick and soft horn button purposedly designed to function as a shock absorber in case of an accident.

Additionally it mentions on another page again the horn button but also the black coating of the spokes a “safety feature”:

2.6.2 Two dephts for different humans

There are also two different dephts of steering wheel. One for the japanese and one for the rest-of-the-world market. The reason was, that the engineering team used two different test-dummies (Mannequins) for setting the seating position of the driver correctly.

However they realized that a considered japanese and american average guy needed different steering wheel position due to their size, and therefore preferred an adjustadble steering colum (as standard in most cars today). Because of the limited budget, they instead decided to use two different depths of steering wheels instead, as stated by Uemura in the development book:

Here is a reference sketch they made to set the layout for the different people driving position during the development from the same book:

3. Variants

3.1 Steering ratio / gearing

This is where things get a bit complicated. Either the documentation is unclear or i’m just lost in translation. The Japanese “introduction of the fairlady Z” book mentions following differences from the “regular” S30 and S30-S Car (Fairlady Z) to the PS30 chassis cars (Z432):

1) The first line “Steering wheel rpm” meens how many rotations can be done from full left to full right end stop of the stering wheel:

S30 / S30S: 2,7 full rotations (Same for the 240Z, if you check the previously shown specification)

PS30: 2,5 full rotations (more direct steering)

2) in the second box the “rack stroke amount” (left and right) is

S30 / S30S: 60,7mm for the regular Fairlady (Same for the 240Z, if you check the previously shown specification)

PS30: 55,6mm

I think the differene in the stroke is what then results in the more or less amount of steering wheels rotation required.

For my unerstanding this would require a different set of gearing of the steering rack / Pinion system. But if you go to the 1973 japanese parts manual, i can only find a different rack-and pinion (complete setup including linkage) for the PZR, which is not the PS30 (PZ), but the PS30-SB cars (Z432R!)

When you go to only the gear assembly, it even say’s “All”. the thing is if you check all the other components on the parts manual, there is nothing relevant to changing this, which is different to the PS30 cars.

Either my technical understanding is too limited, the documentation is not clear or i am missing an important fact here completely. An interesting topic nevertheless. Personally i would have expected a different Assy for the PZ(R) cars from the regular Z-versions. Maybe some reader can shed a light on this?

UPDATE: After searching the different part lists again, it seems like there are many more variants, which are not described somehwere in my books direclty, but you can find them here. This is the the 1973 european parts manual, where three versions of the rack (see all versions of the complete assembly at the top) are listed:

it seems there were at least three different rack types outside of Japan. one for the coupé variant, one for the 2/2 for Europe, and one for the 2/2 outside of europe (see european microfiches below). I checked some other part numbers and you will find plenty of other part numbers in the different books (for e.g. Australian microfiches), so i’ll leave it up to you to find what you need. but just so you’re aware that there were a range of different gear ratios for the different car types and markets.

Additionally i got following input by Alan Thomas (hat tip, sir!):

Japanese market racks were mostly 15.8:1 ratio and most Export market racks (even the RS30/RLS30) followed suit. When the GS30 2/2 was introduced in the Japanese market the factory literature pointed out that they had given it an 18.0:1 rack ratio in contrast to the other Japanese models (its in the Nissan Service Shuho booklets). So it was the North American market (at 17.8:1 ratio from the beginning) that was the exception until the G-prefix 4-seaters matched them. The rack ratio difference is noticeable between – for example – my 1970 HLS30-U and 1970 S30-D. The 17.8:1 is lighter and ‘slower’, probably tuned to the expected tastes of the North American market of the period.

And here is the said Service Shuho scan by Alan to prove it:

And another ony by Alan to confirm the 15.8:1 ratio:

Another reference for the UK & Euro export market cars being 15.8:1 ratio, from the Nissan publication SM5E-0S30G0 workshop manual for the UK & Euro RS30U/GRS30U/RLS30Q/GRLS30Q variants:

And another confirmation from the 1976 Nissan Service specification booklet by Nissan (Thanks Florian!):

3.2 Steering rack bushings

If you look into the parts manual, you will see that there are different versions of the steering rack bushings for “european” and “exluding european” car versions (not all variants are shown in the list below),

In the 240Z Modification bulletin of 1972 (basically the one where the “final spec” european cars differenes are introduced), you can see the following information about the harder rack mounting bushings for european cars:

This was most probably done for the same reason as the general redevelopment of many small areas for the european market cars with “sportier” handling (harder suspension, spoilers for high-speed stability, 5-speed transmission, stabilizer bars, etc)

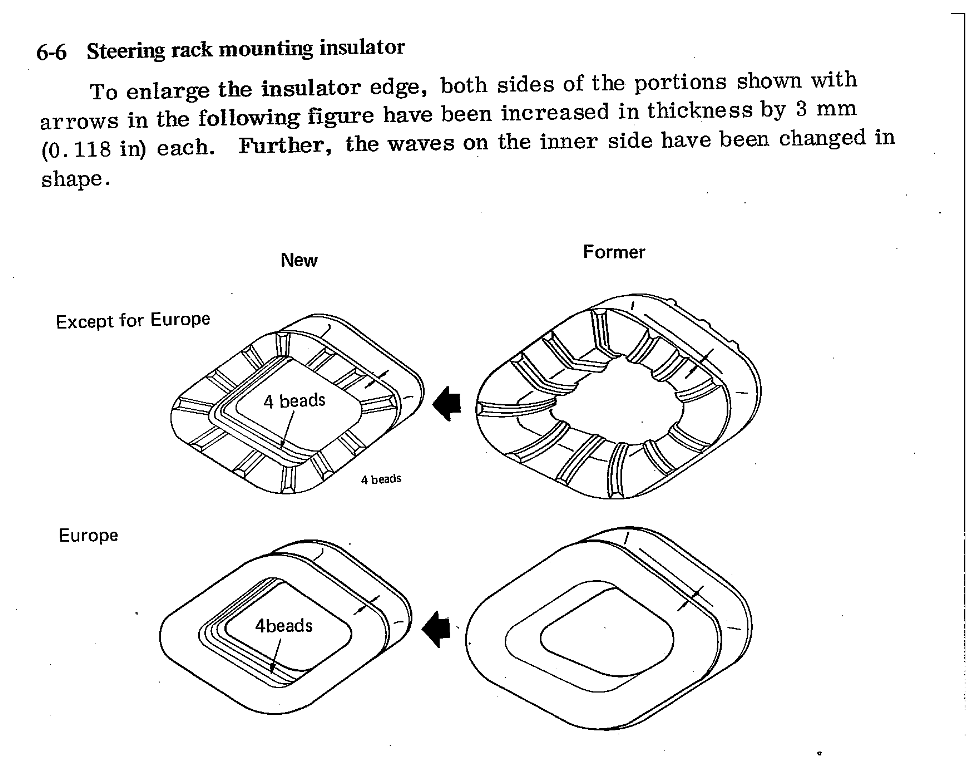

Here’s an example from the later 260Z (1974 modification bulletin) on a similar difference between european and non-european cars:, where you can see that european cars came with a more “solid” bushing design:

3.3 Steering Knuckles

–> see Chapter 5.3

4.Maintenance / Adjustment

In case of problems, or need for improved settings, refer to the Factory Service manual, which provides excellent information and step-by-step manuals on how to disassemble, assemble and adjust all the parts, as shown below in the 1972 USA FSM:

If you speak any japanese (maybe there is an english version too?) the “nissan steering service manual” book gives you some additional service details:

5. Tuning & Modification

5.1 Bushings

If you own an Non-european car, you can of course go for the harder European bushings, which were also sold for e.g. in the US as competeition parts under the same part number as the european car’s standard item:

In the 1987 Nissan Motorsport parts catalogue, you can find the additional confirmation that those parts were originally designed for the european cars:

Of course there are more modern polyurethane bushings like for e.g. the Prothane or Energy bushings, which i use in my car

The vintage Book “how to modify your Datsun”, mentions to put shims around your original bushings to improve the steering feel, but i think this “issue” can also be solved by using more modern and harder PU-bushings.

5.2 Steering coupler / damper

The rubber coupling that connects the steering column to the rack-and-pinion system is another part that can be exchanged. The harder you make it, the more direct the feeling gets, but most probably also more vibrations.

There are again Polyurethan bushings available from various suppliers, but also rock solid (aluminum) “damper eliminators” like the one shown here from Kameari Engine works (JP):

5.3 Steering knuckles

As you can see in the below Nismo / competition parts catalogue picture, also a set of shorter steering knuckles were offered by nissan as an official competition part.

I own a set (see below) and you can find more details about it (including a comparison to the original ones) here:

As Alan and Kats pointed out (thanks for your valuable input!):

The E4201 and superceding E4202 ‘short’ 105mm knuckles were standard equipment on the PS30-SB 432-R model and Sports/Race Options for other models. This is not very clearly written up in the factory literature (quite a lot of the 432-R specific data was like that…) but it is factual.“

5.4 steering gear

I thought it would be possible to switch from the regular to the PS30 steering rack for a more direct feeling, but see my notes in 3.1 that this may be just be a technical misunderstanding from my side?

5.5 Power steering

If you want a more modern and lighter steering feeling, there is the possibility to add electrical power steering to the 240Z. I have not really investigated in this topic, but a quick google search revealed various bolt-in kits available from companies like

Zpowersteering.com (shown in photo below)

Silverminemotors.com

Retrorack.co.au

EZpowersteering.nl (thanks for the Input to Florian)

etc. If you search enough,. there might even be a japanese manufacturer / supplier for something similar, if you prefer that

6. Later versions (260Z)

In the introduction bulletin of the 260Z (september 1973 issue), Nissan mentions a lot of changes.

– different cast metal material and shape of the steering rack

– Retractable column change from bellowes to steel ball type

– Bushing type (see previously shown)

– etc:

See following examples of many changes from the 1973 “introduction of the 260Z” bulletin:

the 1974 december bulletin (modification of the 260Z) mentions again new bushings but it uses the same photo as in the previus “introduction” bulletin.

again Europe got harder (or at least different) bushings than the rest of the world

7. Restauration

If you are wondering how to get from this…:

…to this:

Click the following links to see how i did it. Please follow the original FSM. This is just for your info and i’m not saying a profesional service technician wouldn’t do it better. Back at the time i didn’t even have a dedicated workshop.

Steering rack disassembly

Steering rack assembly Part 1

Steering rack assembly Part 2

Steering rack assembly complete mockup

Steering Colum disassembly

Steering colum disassembly

Steering colum bearing removal

Steering colum assembly

8. More

Interested in more 240Z knowledge posts? click HERE to find more topics like this.

Thanks for reading and i hope you enjoyed it. Feel free to leave your comment below.

I’ll end this post with a photo of my restored steering colum (including cleaned bearing balls and all), ready to go back into the car.

5 Comments

Charles

As usual, an excellent article and an excellent source of information!!

Although. I’m not gonna lie, I expected a part about the steering column U-joint that started non serviceable (in theory – but you can remove it with the help of a dremel) to the more usual serviceable with Circlips.

Did you find informations about that? Why and when did this change?

Given the amount of play numerous of us have there, I suspect the engineers found out about the need to service/replace these U Joints?

JDMjunkies.ch

Hi there. Thanks for your feedback.

Umm that sounds interesting. i didn’t know about that.

Seems like a topic to investigate in when i find some time. Usually you can find the changes in partnumbers when you check the parts manual where you can see the different numbers and until when they were used. I didn’t find any information on that change in my books so far, so it might be that it was in some technical bulletin which i don’t have or not mentioned at all.

Lolman77

Correct. The part number seems to not have changed.

I’m wondering if some where somehow swapped for serviceable ones with circlips but it was a long time ago and nobody knows anymore, or if it was really changed in the factory.

According to forums, it’s the later. But forums aren’t really the most riabke source

My u joint is the non serviceable type, with 4 punches on each side to hold it in place

Loan77

I read your steering rack restoration but forgot: did you manage to change yours?

JDMjunkies.ch

Hi again. I haven’t changed the U-Joints yet. the Rod is the only thing that i haven’t restored yet is the steering column “rod” where this u-joint is attached. so i will definitely look at it the next time i have it on my workbench